Image 1 of 10

Image 1 of 10

Image 2 of 10

Image 2 of 10

Image 3 of 10

Image 3 of 10

Image 4 of 10

Image 4 of 10

Image 5 of 10

Image 5 of 10

Image 6 of 10

Image 6 of 10

Image 7 of 10

Image 7 of 10

Image 8 of 10

Image 8 of 10

Image 9 of 10

Image 9 of 10

ENDIzLED-66

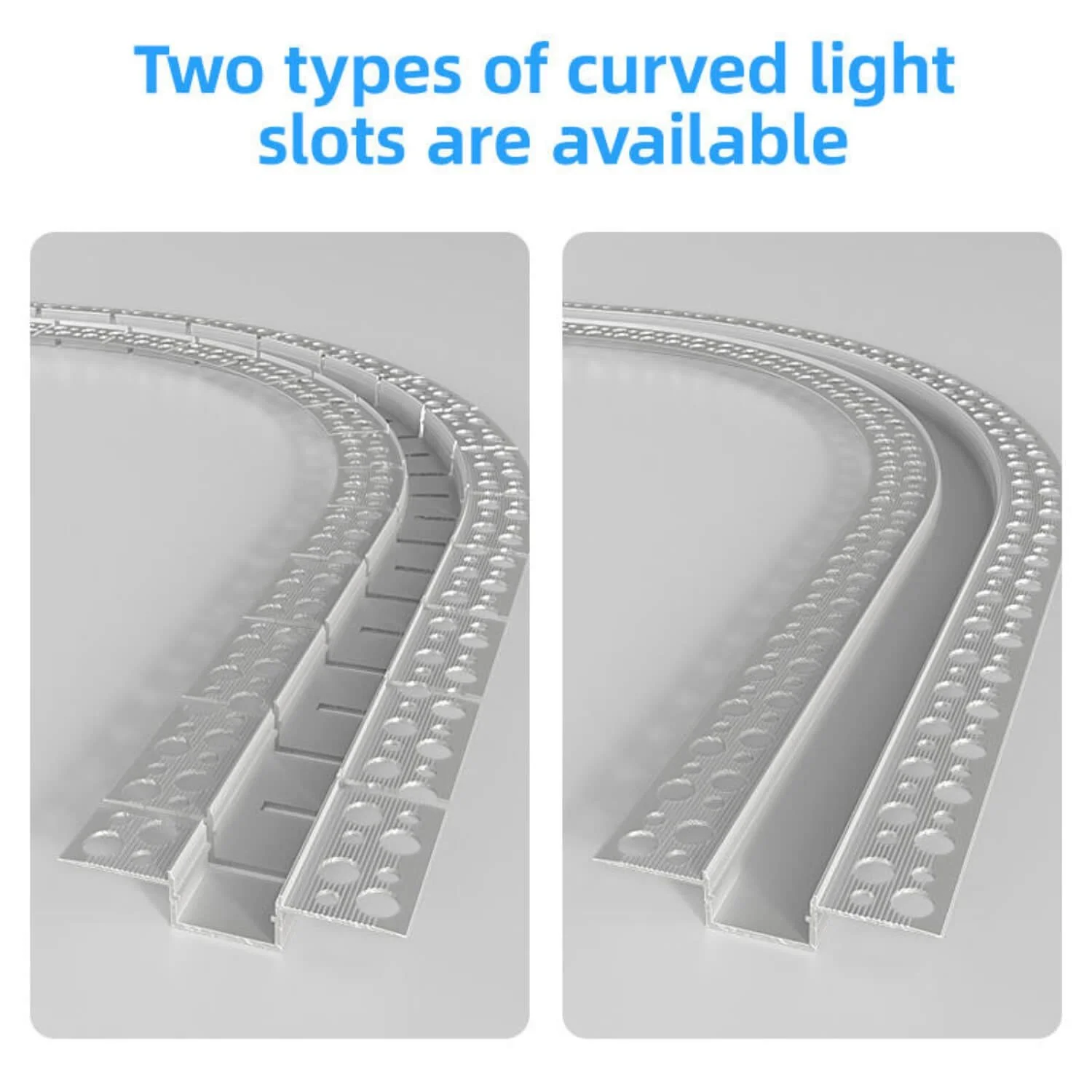

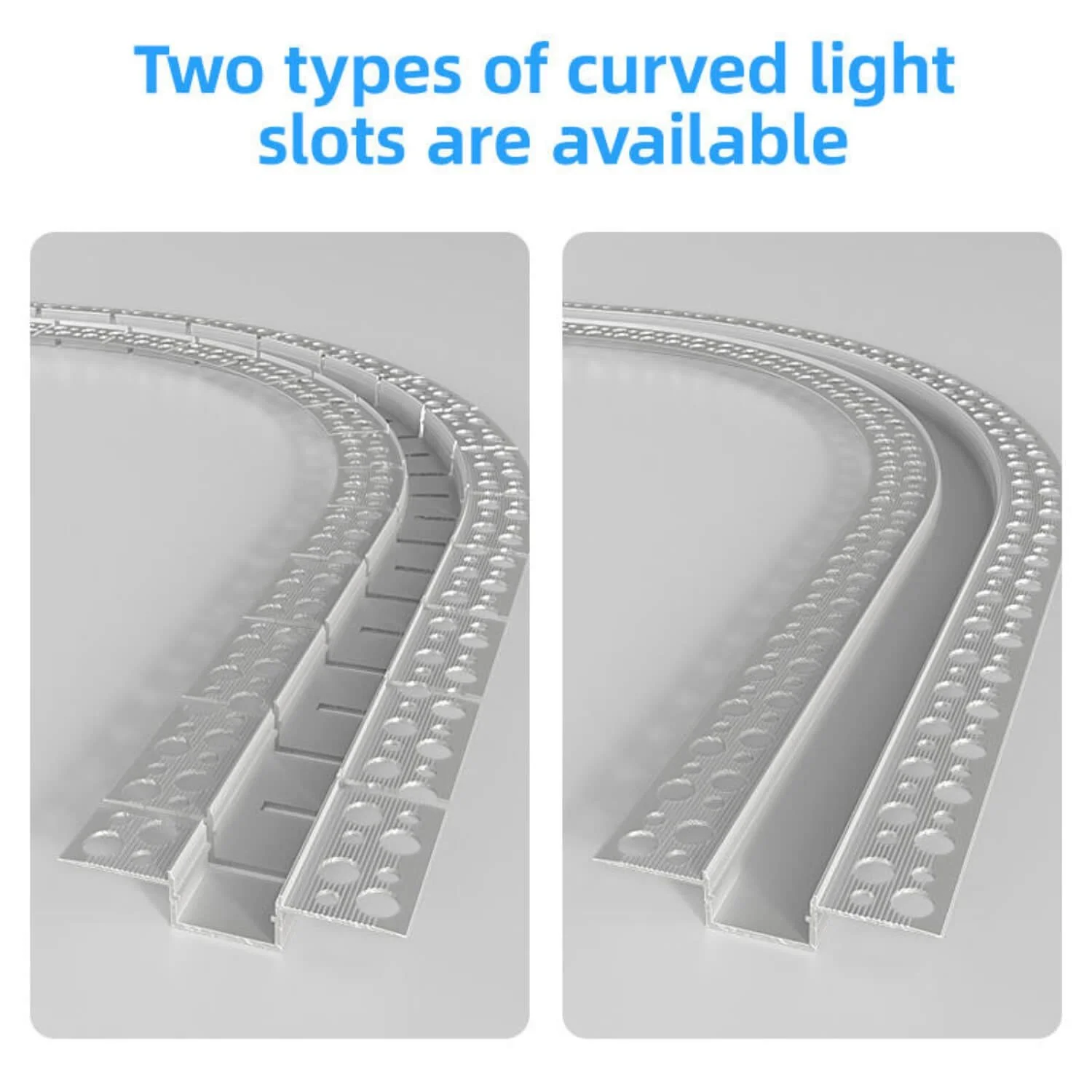

endizled-66 — Bendable LED Strip Profile

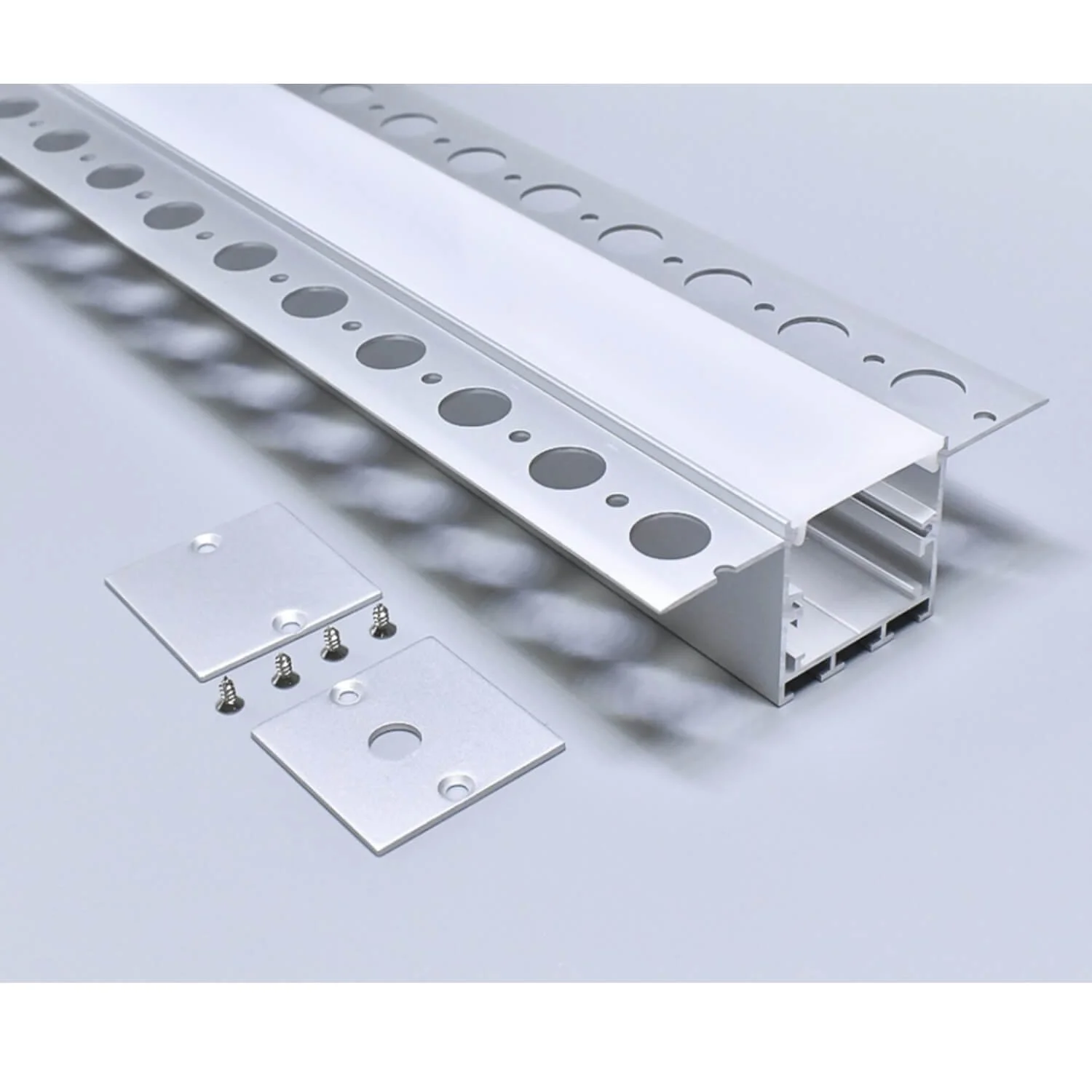

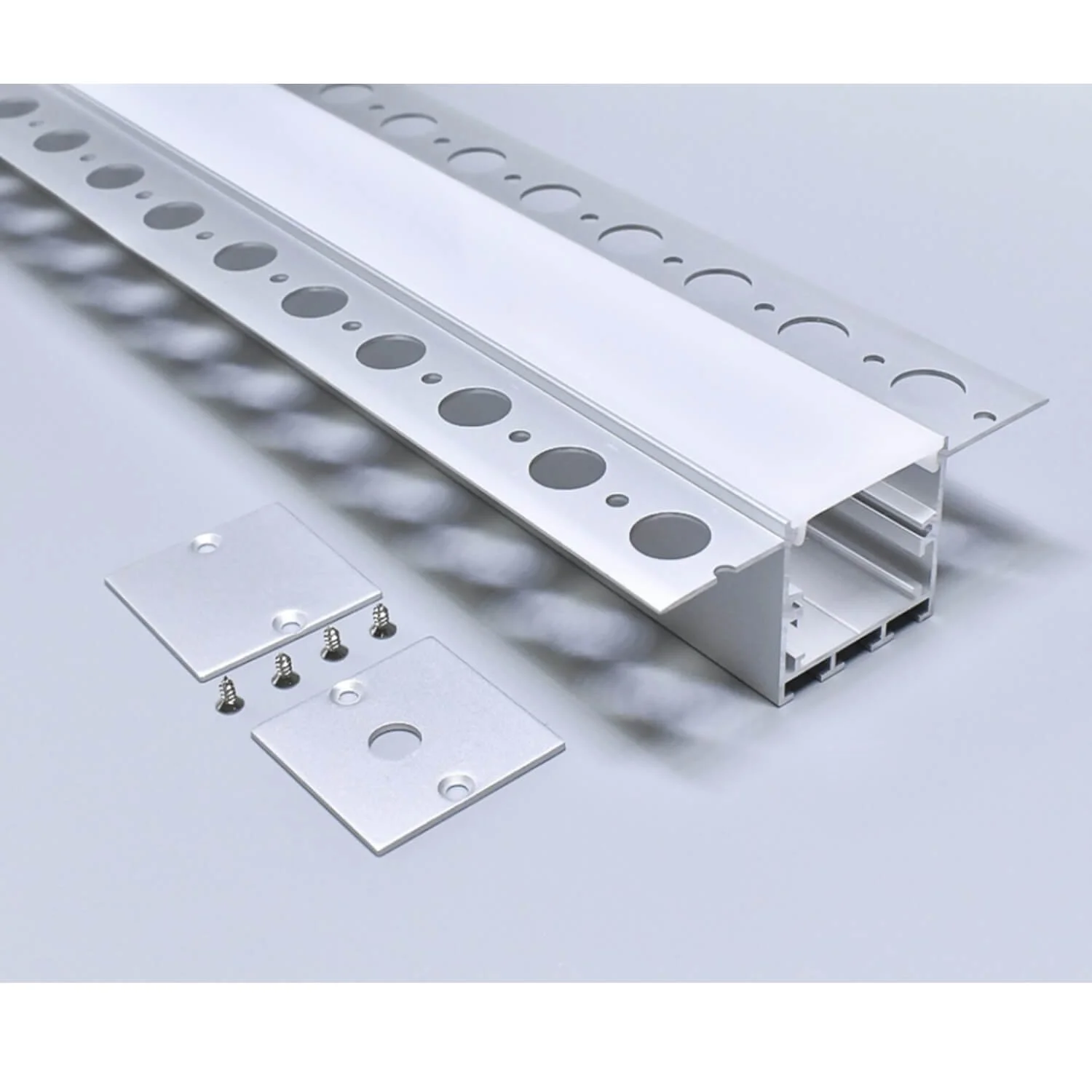

Bring a crisp, professional linear light finish to plasterwork, coves and ceilings with the endizled-66 recessed LED profile. Designed for contractor-level installation and high-end interior projects, this aluminum channel gives you clean shadowlines, reliable heat dissipation and an invisible plastered edge for a seamless built-in look.

Key features

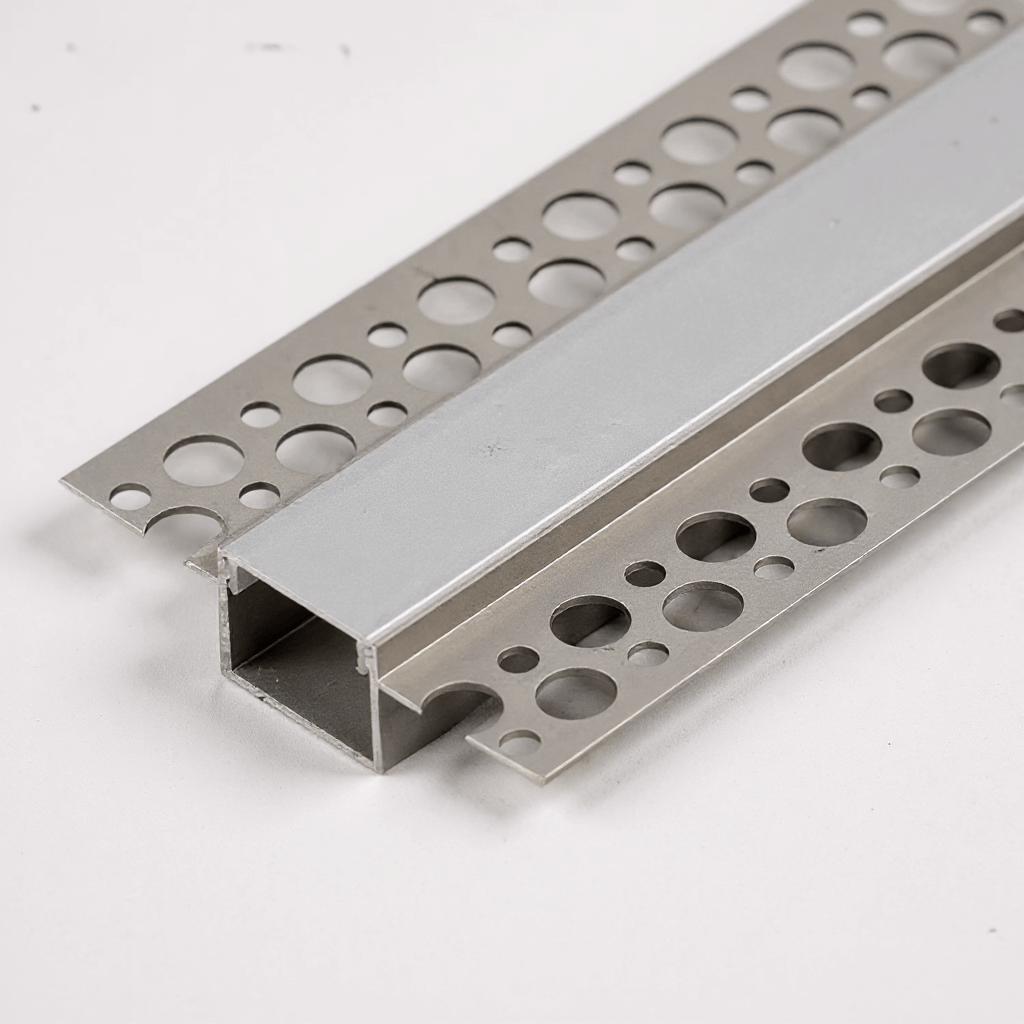

- Sleek plaster-in design with perforated flanges for secure embedding in gypsum, plaster or joint compound.

- Extruded aluminum body for excellent heat dissipation and long LED life.

- Frosted PC diffuser for even light distribution and reduced glare.

- Fits LED strips up to ~10 mm wide (internal channel width 9.8 mm).

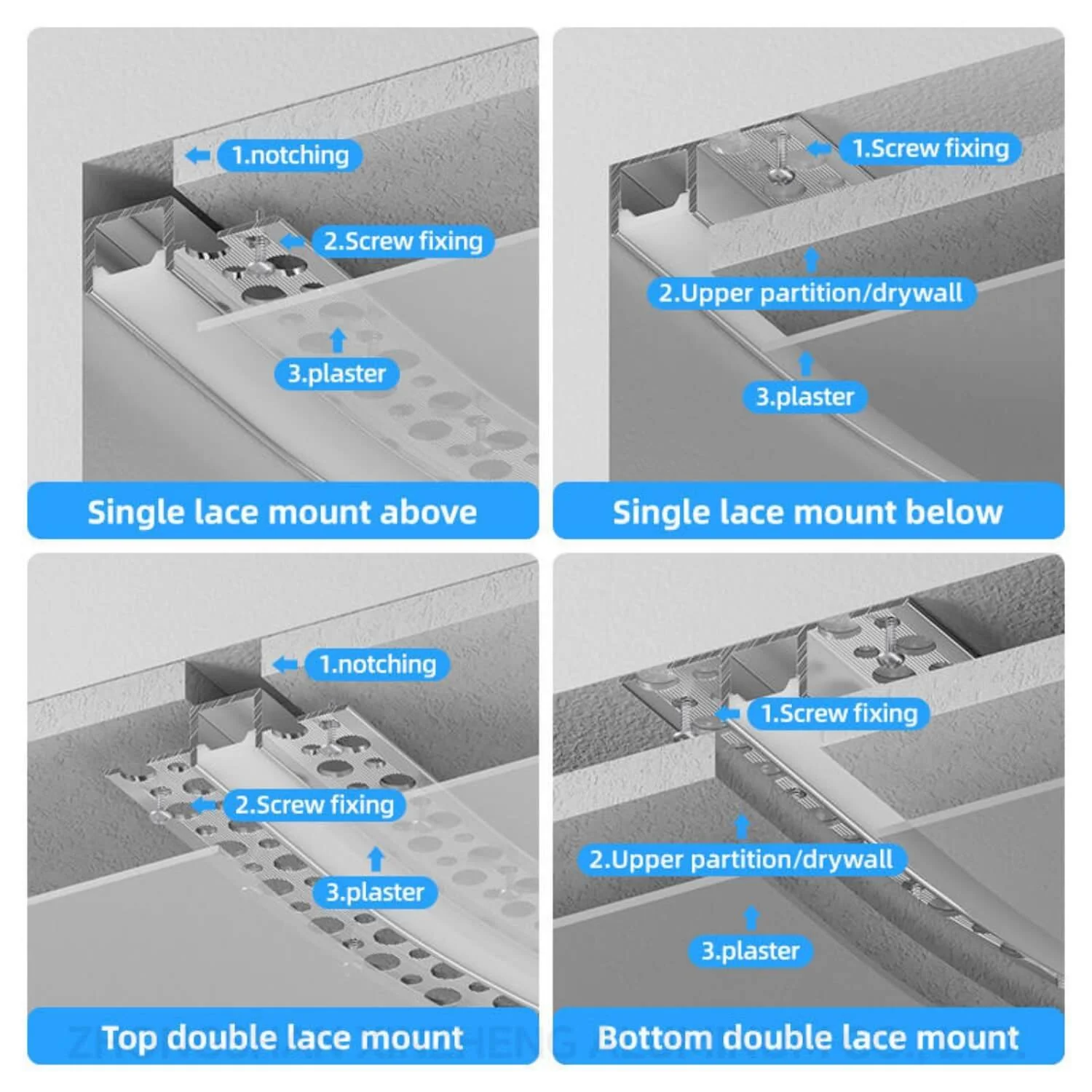

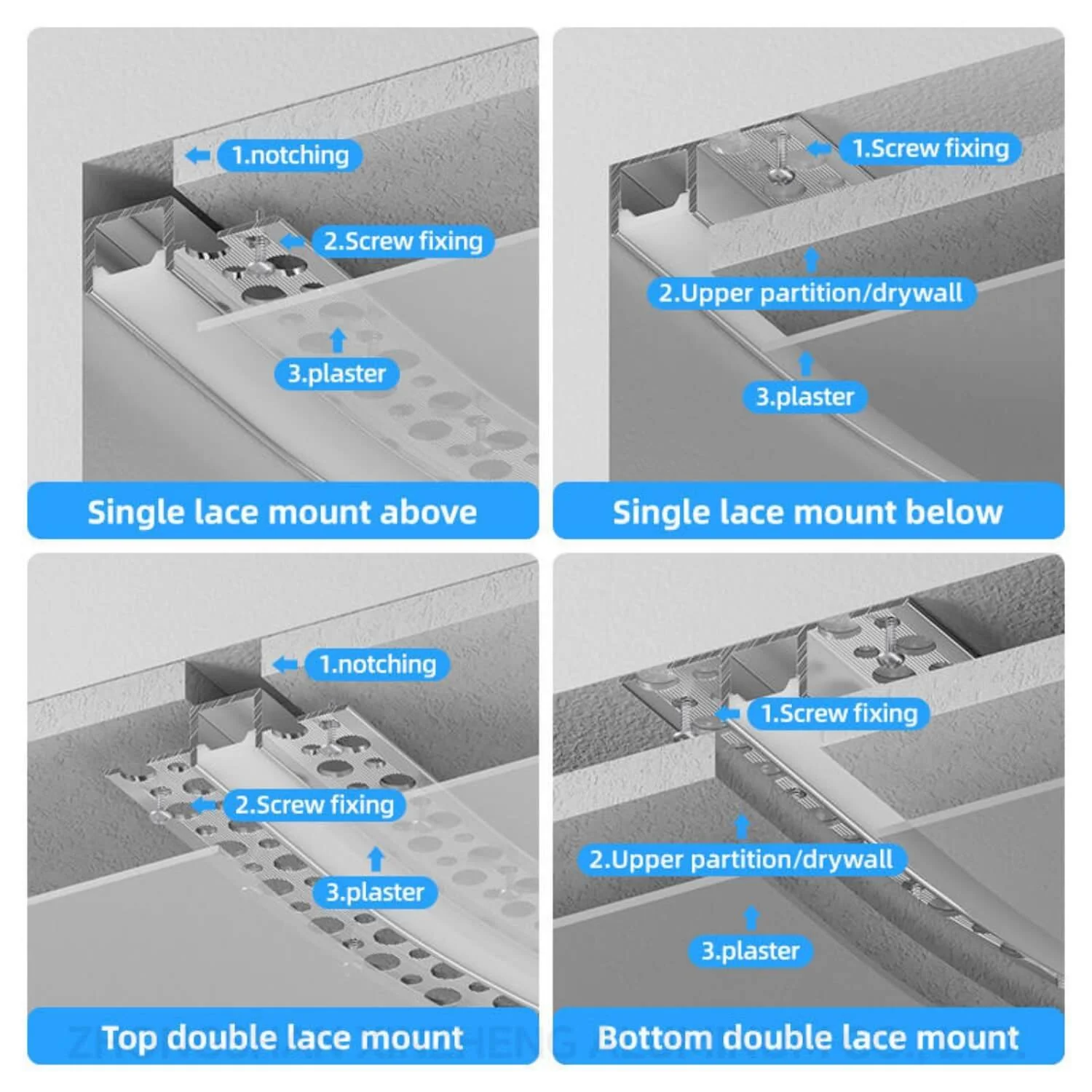

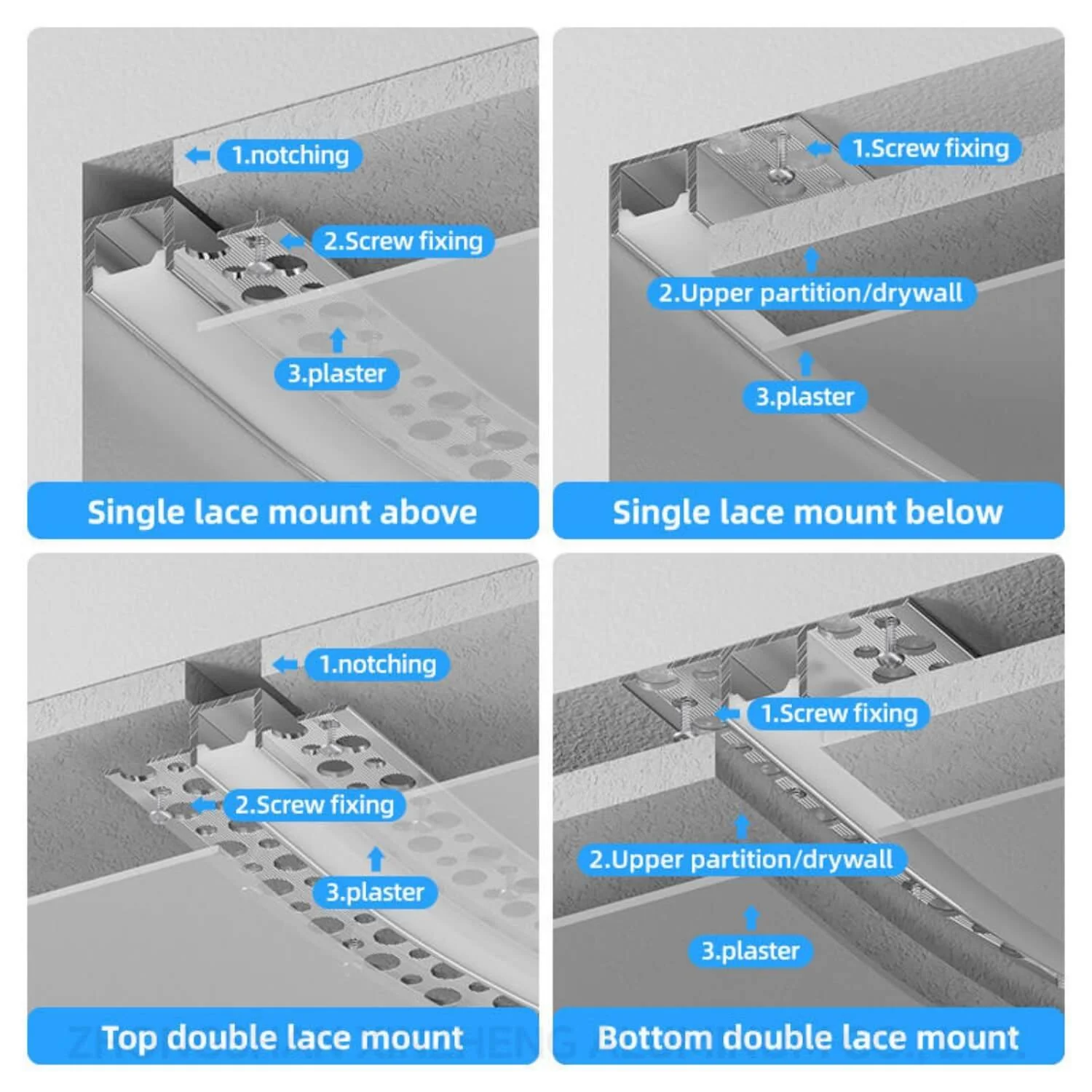

- Multiple mounting options: single lace mount (above or below), top double lace mount, bottom double lace mount — flexible for different ceiling and partition constructions.

- Clean architectural shadowline once plastered — ideal for coves, steps, niches and perimeter lighting.

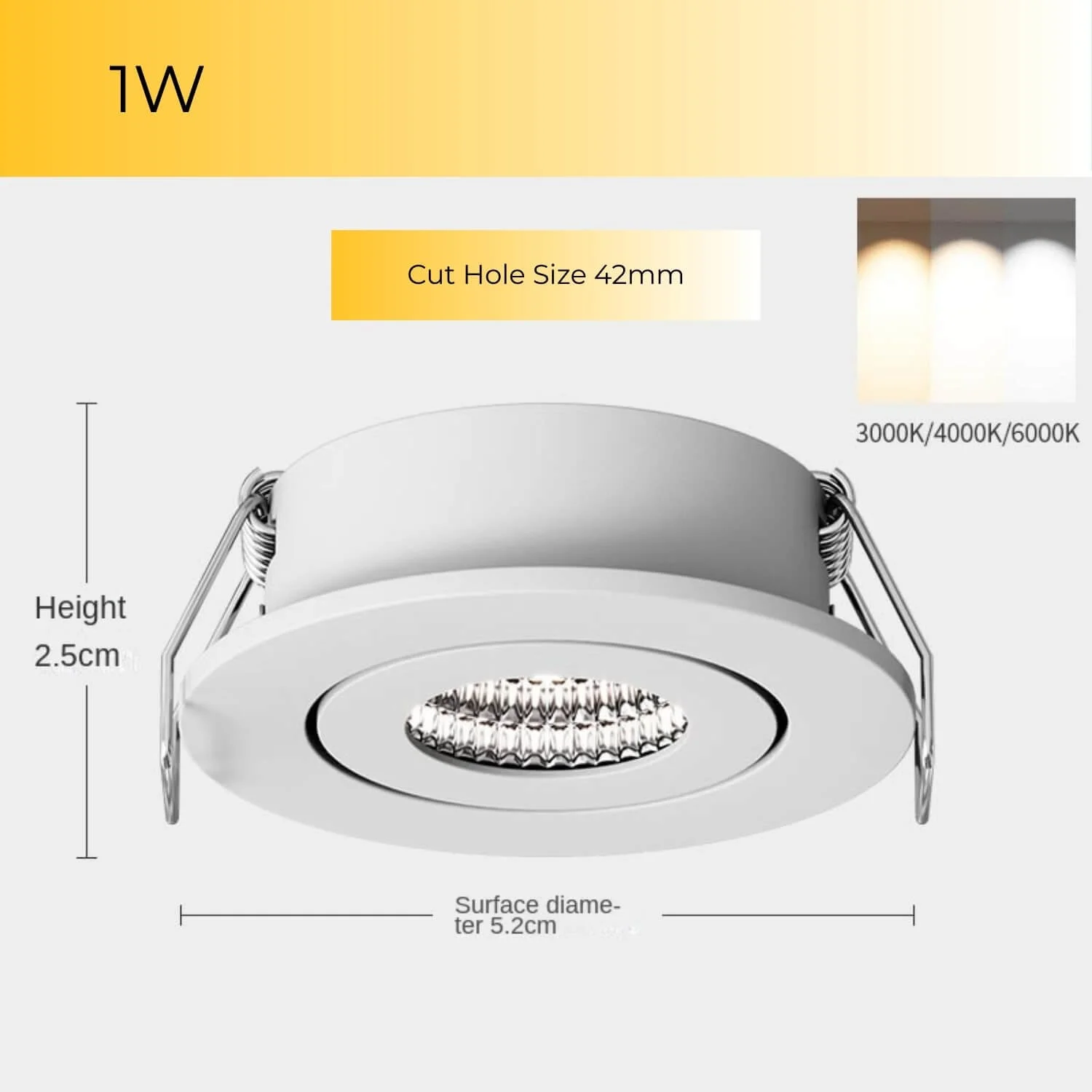

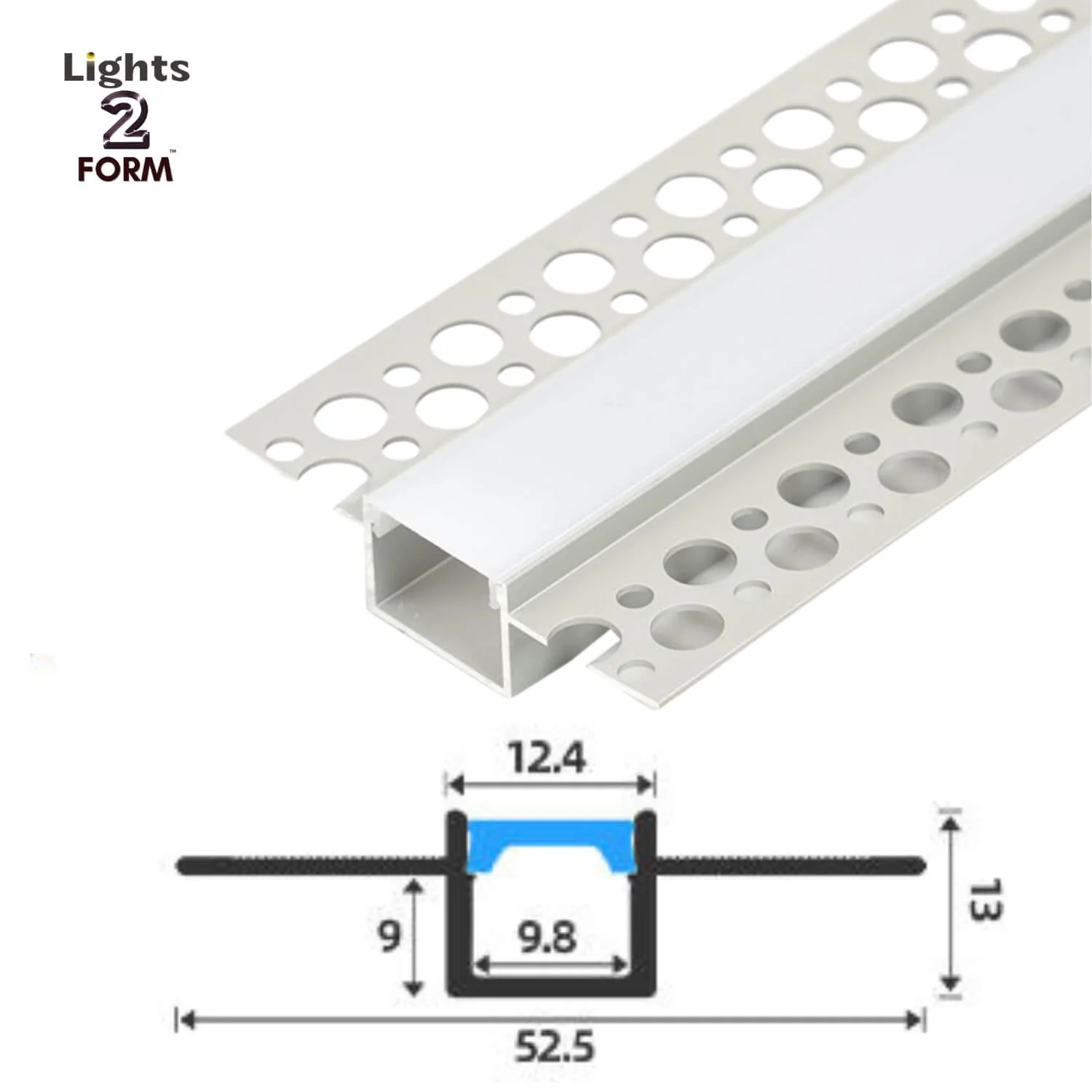

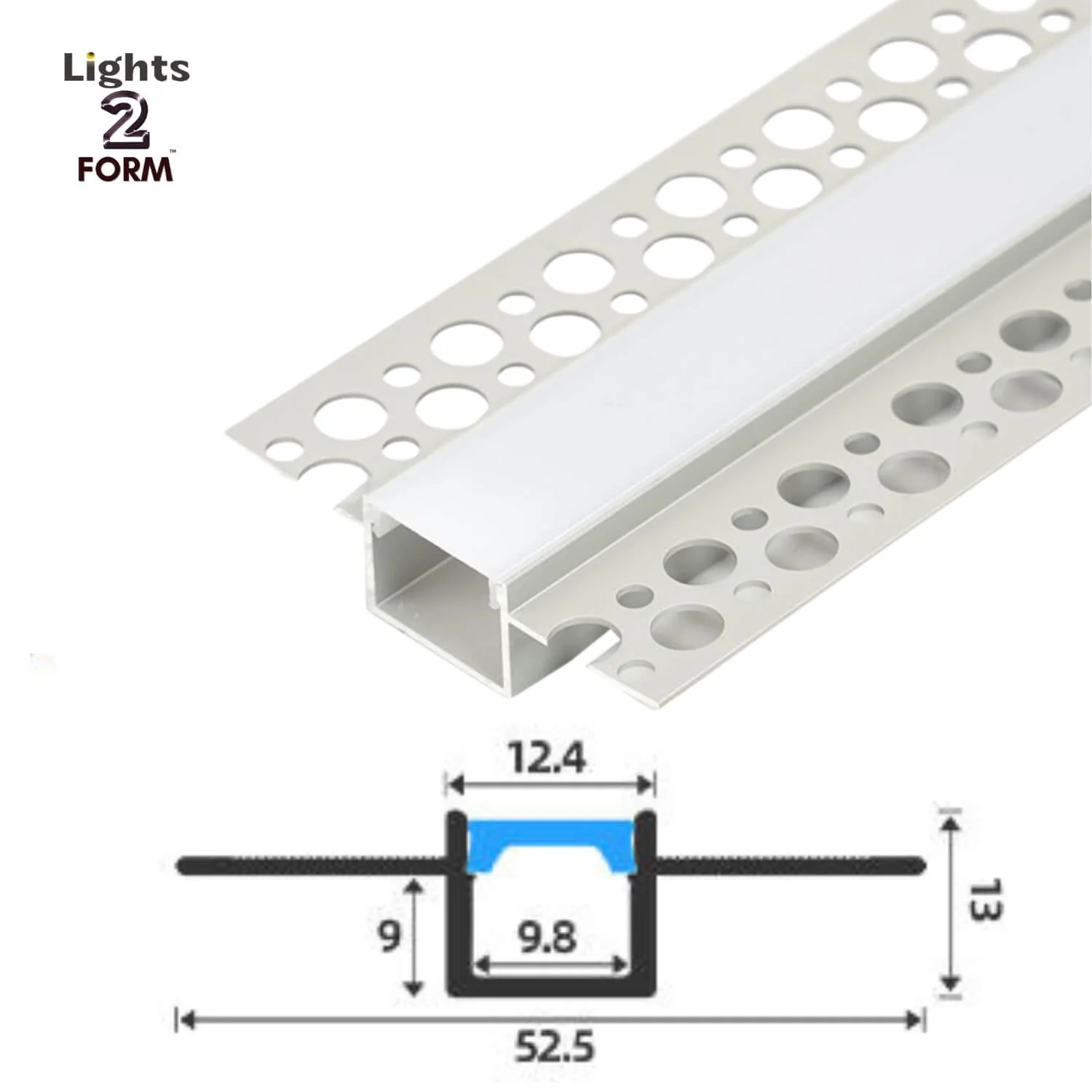

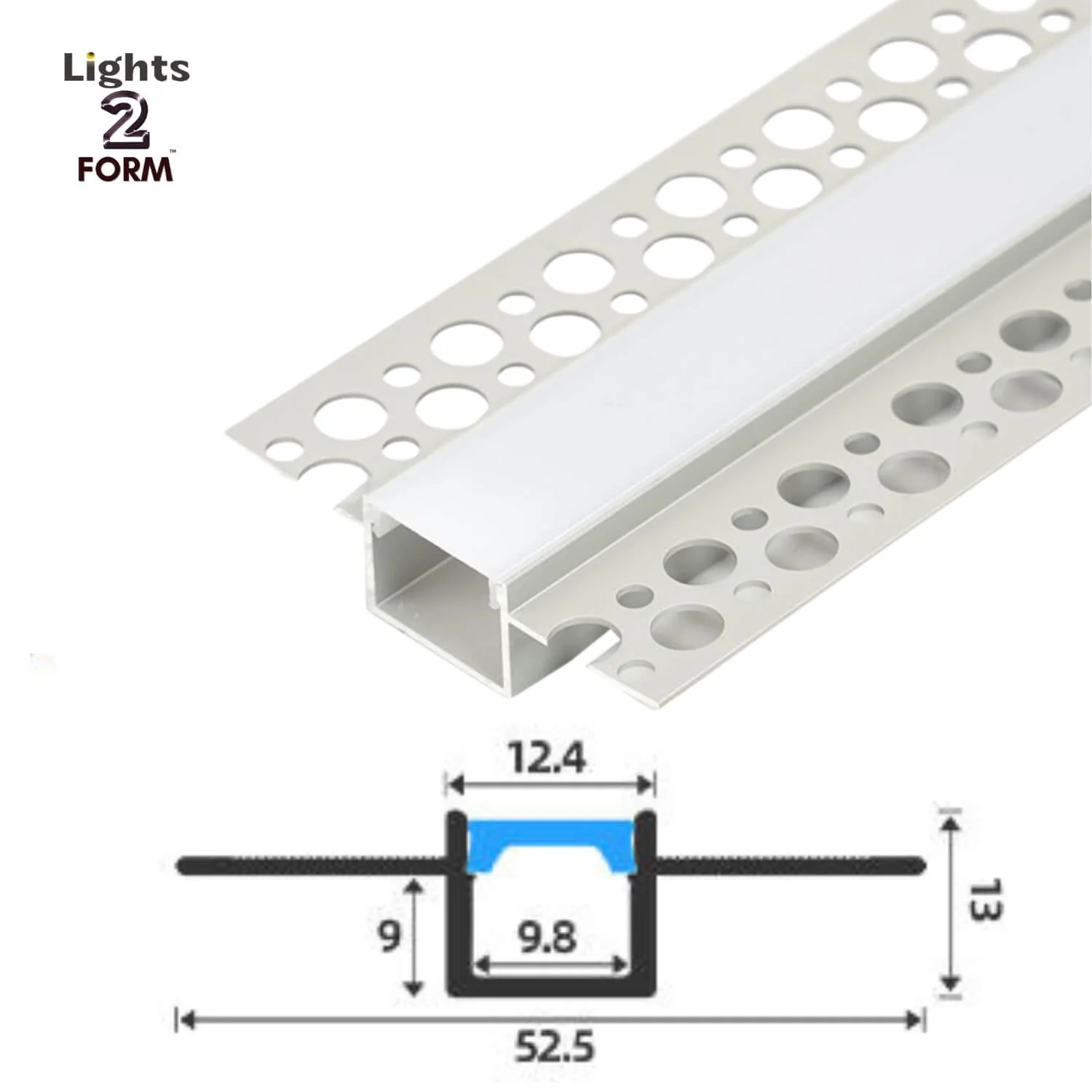

Technical specifications (approximate)

- Overall profile width: 52.5 mm

- Internal channel width: 9.8 mm (max LED strip width)

- Diffuser width: 12.4 mm

- Recess depth / internal height: 9 mm

- Visible flange/finished height: ~13 mm

- Materials: extruded aluminum profile, frosted polycarbonate diffuser

- Finish: white-ready flanges for finishing with plaster/compound

Why choose endizled-66?

- Professional finish: Perforated flanges bond with plaster for a flush, seamless result with crisp edges.

- Efficient cooling: Aluminum body keeps LED strips running cooler for longer life and consistent output.

- Versatile installation: Designed for multiple recessed mounting approaches to suit ceiling and partition layouts.

- Balanced light: Frosted diffuser softens hotspots and gives an even linear wash.

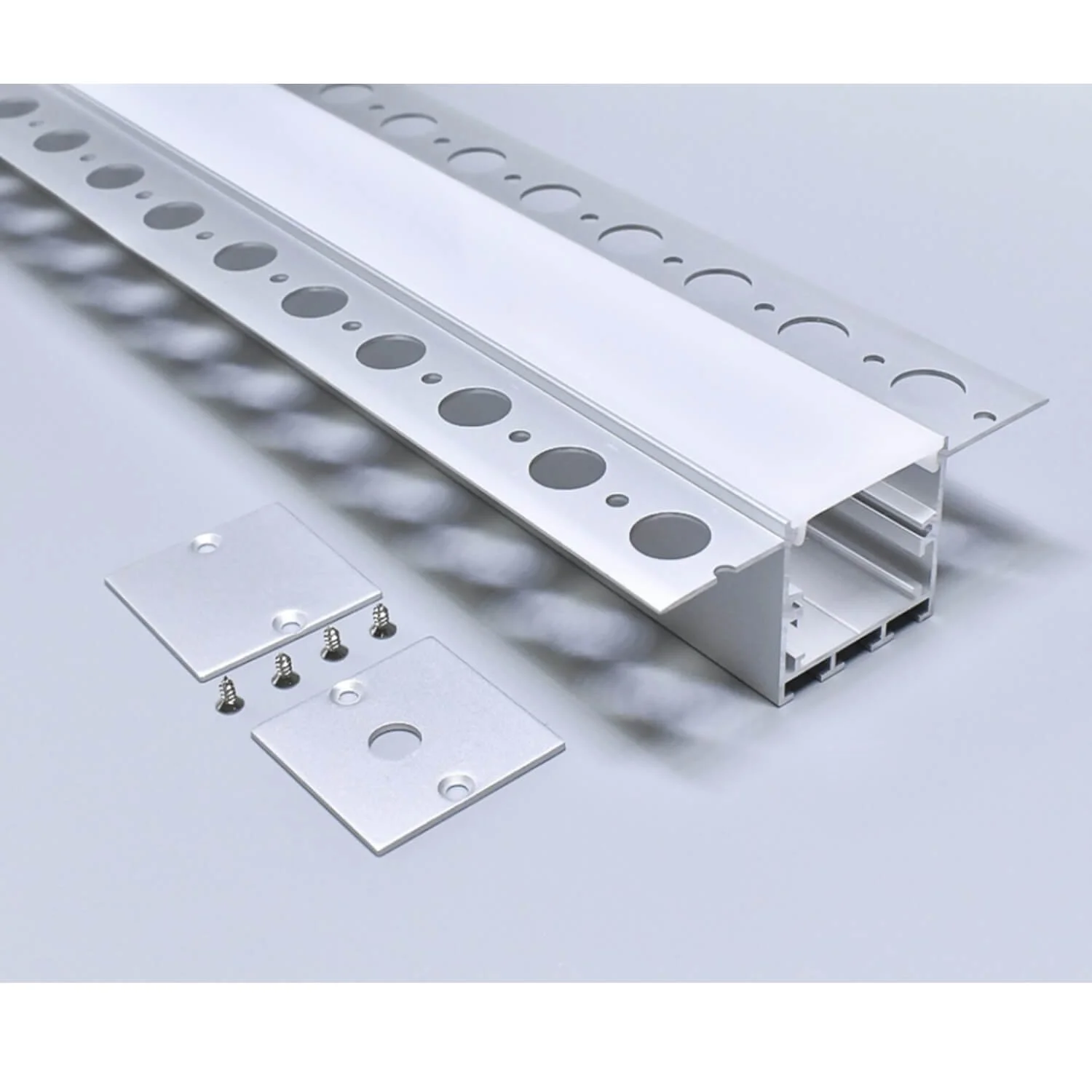

Installation tips

- Use appropriate LED tape no wider than 10 mm. Secure strip inside the channel before plastering.

- Fasten profile to the substrate (screws or notching) per the chosen mount method, then embed flanges into plaster/joint compound.

- Trim diffuser to length and push-fit after plaster cures for a clean final look.

endizled-66 — Bendable LED Strip Profile

Bring a crisp, professional linear light finish to plasterwork, coves and ceilings with the endizled-66 recessed LED profile. Designed for contractor-level installation and high-end interior projects, this aluminum channel gives you clean shadowlines, reliable heat dissipation and an invisible plastered edge for a seamless built-in look.

Key features

- Sleek plaster-in design with perforated flanges for secure embedding in gypsum, plaster or joint compound.

- Extruded aluminum body for excellent heat dissipation and long LED life.

- Frosted PC diffuser for even light distribution and reduced glare.

- Fits LED strips up to ~10 mm wide (internal channel width 9.8 mm).

- Multiple mounting options: single lace mount (above or below), top double lace mount, bottom double lace mount — flexible for different ceiling and partition constructions.

- Clean architectural shadowline once plastered — ideal for coves, steps, niches and perimeter lighting.

Technical specifications (approximate)

- Overall profile width: 52.5 mm

- Internal channel width: 9.8 mm (max LED strip width)

- Diffuser width: 12.4 mm

- Recess depth / internal height: 9 mm

- Visible flange/finished height: ~13 mm

- Materials: extruded aluminum profile, frosted polycarbonate diffuser

- Finish: white-ready flanges for finishing with plaster/compound

Why choose endizled-66?

- Professional finish: Perforated flanges bond with plaster for a flush, seamless result with crisp edges.

- Efficient cooling: Aluminum body keeps LED strips running cooler for longer life and consistent output.

- Versatile installation: Designed for multiple recessed mounting approaches to suit ceiling and partition layouts.

- Balanced light: Frosted diffuser softens hotspots and gives an even linear wash.

Installation tips

- Use appropriate LED tape no wider than 10 mm. Secure strip inside the channel before plastering.

- Fasten profile to the substrate (screws or notching) per the chosen mount method, then embed flanges into plaster/joint compound.

- Trim diffuser to length and push-fit after plaster cures for a clean final look.